The integration of Supervisory Control and Data Acquisition (SCADA) systems in control rooms has revolutionized how critical infrastructures operate and are managed. This article delves into the essence of SCADA systems, its operational dynamics in control rooms, and the symbiotic relationship with the Human-Machine Interface (HMI).

SCADA is an advanced system used for monitoring, controlling, and acquiring data from various processes and operations in industrial settings. In utility facilities, SCADA ensures efficient, reliable, and safe operations. It collects real-time data from sensors and other devices, processes this data, and enables operators to make informed decisions based on up-to-the-minute information.

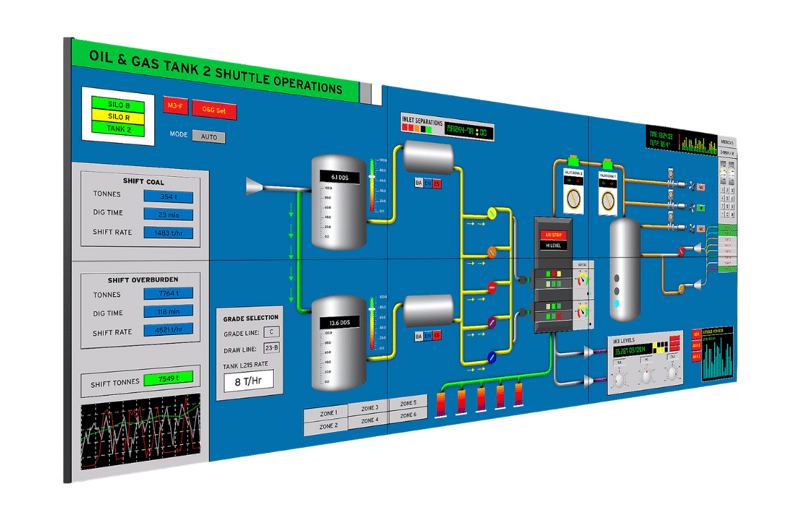

Before integrating the SCADA system into your control room, let's explore what makes up a SCADA system in a common control room. While not an exhaustive list, in general, the key components of a SCADA system are:

Purpose: Alarm systems notify operators of process anomalies, equipment failures, or safety hazards. They are essential for preventive maintenance and emergency response.

SCADA does not exist in a control room in isolation; it’s a part of a complex system of operational inputs. Here’s a list of the typical inputs and systems found in the control room of a utility facility:

These systems are integrated to create a comprehensive view of the operations, ensuring safety, efficiency, and regulatory compliance in the environments of a typical utility company.

So, while the SCADA system is central to the functionality of a control room, it represents just one element of a much broader array of technologies and systems that must work in concert to ensure operational success.

Designing a control room is not about SCADA system integration; it involves crafting a holistic environment where every system—from communication protocols to environmental monitoring—works seamlessly together. Remembering that SCADA is part of a larger system underscores the need for a complex approach when building and updating control room infrastructures.

As technology evolves and systems become increasingly complex, the need for sophisticated, user-friendly control environments grows ever more essential. With over 40 years of experience, Evans focuses on enhancing your operations by building comprehensive, secure, and easy-to-use control rooms tailored to your industry's needs, including SCADA systems integration. This deep expertise ensures you get control environments that are not only efficient and resilient but also keep pace with technological advancements and changing requirements.

As we've seen, SCADA systems are crucial in today's industrial operations. But as technology advances and utility management becomes more complex, there's a growing need for even more sophisticated systems. This is where Advanced Distribution Management Systems (ADMS) come into play as the next step in tech evolution. In our next blog post, we’ll dive into how ADMS builds on and significantly enhances SCADA capabilities.

Subscribe to our blog today for expert tips, news, and insights on the control room industry.